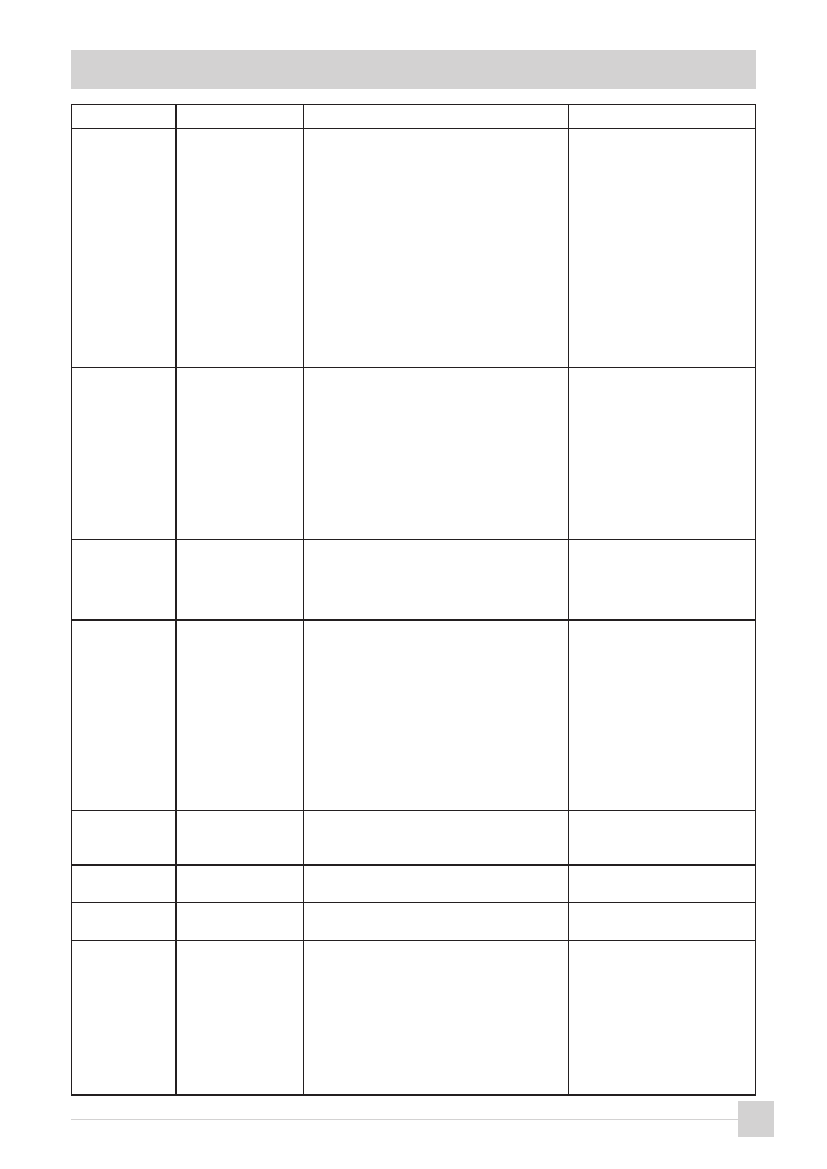

Table 3: Remedies for Common Problems in Operations & Maintenance

Indication

High generator

voltage

Possible reason

Ballast heater

burnt

Remedy

Replace the relevant heater element

Ballast breaker

Replace relevant heater element

gets switched off Replace the relevant breaker (MCB)

Comments

Relevant ballast voltage in-

creases when ballast heater

is burnt or ballast breaker

gets switched off.

Faults in TRIAC

(Tirade Alternating

Current Switch) /

thyristor

Replace them

Low Generator

voltage

Capacitor fault

Valve block

Check the capacitor bank. If there is a

damaged capacitor, replace with a ca-

pacitor of same value

Check the valves for blocking / clean

them

Replacing TRIAC / thyristor

– this has to be done by a

competent electrician.

Frequency increases when a

capacitor is at fault.

High frequency

Not enough water

Ballast fault

Capacitor bank fault

Check whether pressure gauge gives exact

pressure, whether enough water flows into

the forebay tank and whether there are

any leaks or blocks. If so remedy them.

Close one valve if there is a multi-jet

turbine and run with the lesser number

of jets.

Replace ballast element

Replace capacitors

With the change in

frequency, the voltage also

changes.

Low frequency

Low ballast

current

High ballast

voltage

Low ballast

voltage

Fluctuation

of the indica-

tor hand of

the electrical

meters

Nozzle block

Not enough water

Damaged heating

element

Damaged heating

element

Damage of TRIACs

or thyristors

Fluctuating load

(consumers

appliances)

Intrinsic errors

in the TRIACs or

thyristors

Check the nozzle and clean

Check trash rack and clean,

mend the trash rack to en-

sure only particles that can

pass through the nozzles are

filtered in.

Check whether pressure gauge gives exact

pressure, whether enough water flows

into the forebay tank and whether there

are any leaks or blocks. If so remedy them.

Close one valve if there is a multi-jet turbine

and run with the lesser number of jets.

Replace ballast element

Replace ballast element

If faulty, replace the respective TRIACs /

thyristors

Check whether highly load varying electri-

cal appliances are used by community

members, and if so, stop it.

Ballast voltage may

increase under this

situation.

Current in ballast may de-

crease in this situation.

Competent electricians must

attend to this.

This will settle with a small

variation in the load (con-

sumption by

consumers)

23